Advanced Product Quality Planning

Original price was: RM2,600.00.RM1,050.00Current price is: RM1,050.00.

|

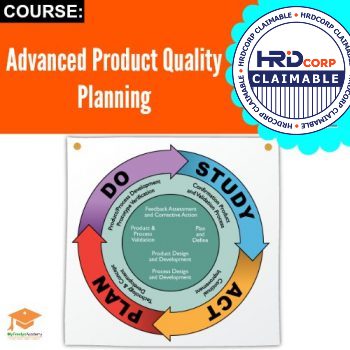

IntroductionAdvance Product Quality Planning (APQP) is established by General Motors, Ford and Chrysler as part of the Quality Planning Process of the Quality Management System. The purpose of the planning process is to ensure that customer needs and expectations are determine and met accurately. How Will You BenefitUpon completion of this programme, the participants will be able to:

Who Should AttendThis course is suitable for MDs, GMs, Managers, Executives and Supervisors who are involved in the planning process. MethodologyThis stimulating program will maximize understanding and learning through short classroom lessons embedded with real practical examples. Module

|

Fee: RM 1,000 per pax

Loyalty Points: 1000 Points

Duration: 2 Days

Note: In-house course is available. Request it HERE

Trainer

Delip Singh

Biodata:

Delip Singh, a dynamic, aggressive and versatile trainer, is a registered EMS Lead Auditor, QMS & OHSAS Auditor with IRCA. He is also an Associate Member of IQM and a registered Consultant with MRCA. Delip specializes in providing trainings for Total Quality Management, Kaizen, Poka-Yoke, Measurement & Calibration, SPC, FMEA, 7 QC Tools, QCC’s, Measurement System Analysis, ISO 9001, ISO/IEC 17025, HACCP, ISO/TS 16949 and OSHAS 18001. The Master’s of Business Administration holder conducts his trainings in a highly interactive fashion, with total participation and blended with practical and real examples. He has provided consultancy services to numerous clients and trained over 340 organizations.