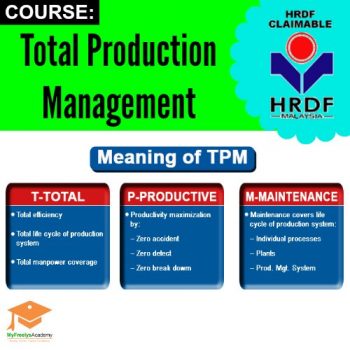

Total Productive Maintenance (TPM) – Introduction Of Autonomous Maintenance

Original price was: RM2,600.00.RM1,450.00Current price is: RM1,450.00.

|

IntroductionKnowledge: This course program is aim to provide knowledge and understanding and practice a step-by-step process for implementing an equipment management strategy involving operators through the cooperation of production, maintenance, engineering & management personnel. This is part of introductory part of Total Productive Maintenance and also to prepare the participants towards the full scale implementation of Autonomous Maintenance, besides the typical preventive and predictive maintenance. How Will You BenefitParticipants should be able to:

Who Should AttendThis course is designed for Managers, Executives, Customer Service, QA, Supervisors and Operators who carry roles, responsibilities and authorities in maintenance activities. Level for Executives and above MethodologyThis program will be conducted with interactive lectures, PowerPoint presentations, discussions and practical exercises Module

|

Fee: RM 1,450 per pax

Loyalty Points: 1450 Points

Duration: 2 Days

Note: In-house course is available. Request it HERE

Trainer

Stephen Lim Kean Jin

Biodata:

Stephen Lim Kean Jin is currently advising and training organizations of various industries in Lean Manufacturing, Six Sigma, Business Excellence Programs, ISO / TS 16949, ISO 9001, 14001, OHSAS 18001, ISO 22000, HSPM QC 080000, HACCP, ISO 13485, Integrated Management Systems and others. His extensive industrial experiences in various sectors included Automotive Product Manufacturing, Paper Cushion & Packaging, Corrugated Carton, Rubber & Plastic (blow molding, injection molding, extrusion); Chemical Industries (pesticide, chemical dilution), Textile and Garment Manufacturing, Metal Products Manufacturing, Wood & Furniture Manufacturing, Printing, Electrical & Electronic Manufacturing, Construction, Medical, Semiconductor and others. He is one of the experts in Quality Management with industrial experiences both as a Consultant / Trainer / Auditor and as a Quality Manager in a leading manufacturing company.He is able to conduct programmes in Bahasa Malaysia and English.