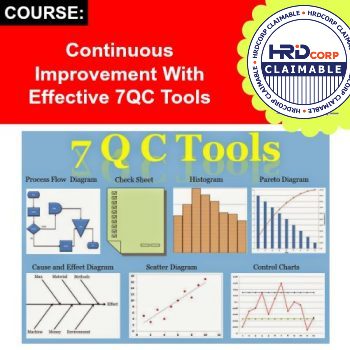

Continuous Improvement With Effective 7QC Tools

Original price was: RM2,600.00.RM1,200.00Current price is: RM1,200.00.

|

IntroductionTo remain competitive in today’s competitive environment, organizations’ operations have to ensure its defined processes are executed efficiently and effectively. Errors in the processes affect the output and delivery quality, unresolved repetitive errors eventually impact cost competitiveness and customer confidence. This course provides a comprehensive understanding on the usage of the 7 Quality Control (QC) Tools as systematic approach to problem solving and fundamental for Continuous Improvement. Participants will be familiarized with these tools in identifying problems/ defects/ rejects, prioritizing problem solving, determining causes, recommending improvements, tracking performance for improvements. ObjectiveUpon completion of this program, the participants will be able to:

Who Should AttendEmployees and team members involved in continuous improvement initiatives including General Managers, Managers, Executives, Supervisors and Operative Personnel from manufacturing and service industries. Level for Executives and above MethodologyThis stimulating program will maximize the understanding and learning through Classroom lecture, Group activity & presentation, Case study and Pre and post test Module

|

Fee: RM 1100 per pax

Loyalty Points: 1100 Points

Duration: 2 Days

Note: In-house course is available. Request it HERE

Trainer

Zulkifli Bin Mahmud

Biodata:

Zulkifli Mahmud is a competent trainer and consultant that provides training sessions and workshops to various companies in industries such as manufacturing and technology. He has a Bachelor’s degree in Mechanical Engineering, as well as a diploma in Supervisory Management. His exposure and experience as a Lead Auditor in different companies led to an improvement of his competency and technical skills. His vast knowledge and strategies on Quality Management function and Maintenance helped him conduct various courses related to such subjects. Zulkifli is also driven to improve professionals and organizations by offering sessions that tackle topics like Safety and Health function, Lean Manufacturing, Strategic Management, Shop Floor Management and Operation Management. With his consultancy services and achievements under his belt, he is one of the in- demand speakers in the manufacturing industry.

Venue

Date