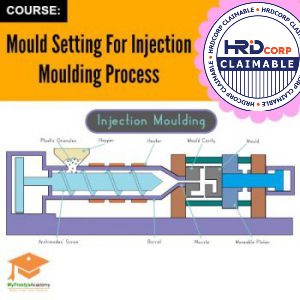

Mould Setting For Injection Moulding Process

Original price was: RM2,600.00.RM1,000.00Current price is: RM1,000.00.

|

How Will You BenefitUpon completion of this programme, the participants will be able to :

Who Should AttendThis course is designed for technical staff (Technician/Engineers) with working knowledge of injection moulding equipment MethodologyThis course will be presented through interactive lecture, group discussion, case study, roll play and games Module

|

Fee: RM 1,000 per pax

Loyalty Points: 1000 Points

Duration: 2 Days

Note: In-house course is available. Request it HERE

Trainer

Mokhtar Bin Ali

Biodata:

Mokhtar Ali has over 10 years of practical experience dealing with the process and machinery used in plastic injection moulding. His training courses include Productivity Techniques for Supervisors, Kemahiran Penting Untuk Penyelia, Plastic Injection Moulding and Mould Design Technology, MC 6021 Injection Moulding Process and MC 6022 Process Trouble Shooting. His training sessions are conducted in an interactive way and encourage utmost participation from those that attend. This ensures that his participants’ interests in the subject are maintained at all times and as a result, his training sessions are very much sought after by many who are looking to learn a more in depth knowledge of this subject.